Spiral Disc Springs for slide gate

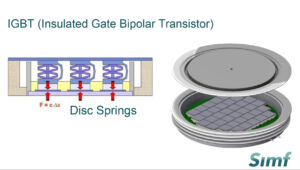

Spiral Disc Springs In the mechanical field, spiral disc springs have become the preferred choice for many engineers and designers due to their unique structure and outstanding performance. Today, let’s delve into the world of materials used in double-coil springs and uncover the secrets behind them. Definition and Applications of Spiral Disc Springs As the name suggests, a double helix spring is formed by two spring wires wound together in a specific pattern. This structure enables the spring to distribute stress more evenly when bearing loads, thereby enhancing its load-bearing capacity and stability. It finds extensive…