Bearings

Bearings are components that supports a shaft. It serves several key functions.

Bearings are a critical component in modern mechanical equipment. Their primary functions include supporting rotating mechanical elements, reducing friction coefficients during motion, and ensuring rotational precision.

First, it reduces friction between the shaft and the supporting structure.

Second, it ensures the shaft maintains its proper position.

Furthermore, it can withstand both axial and radial loads.

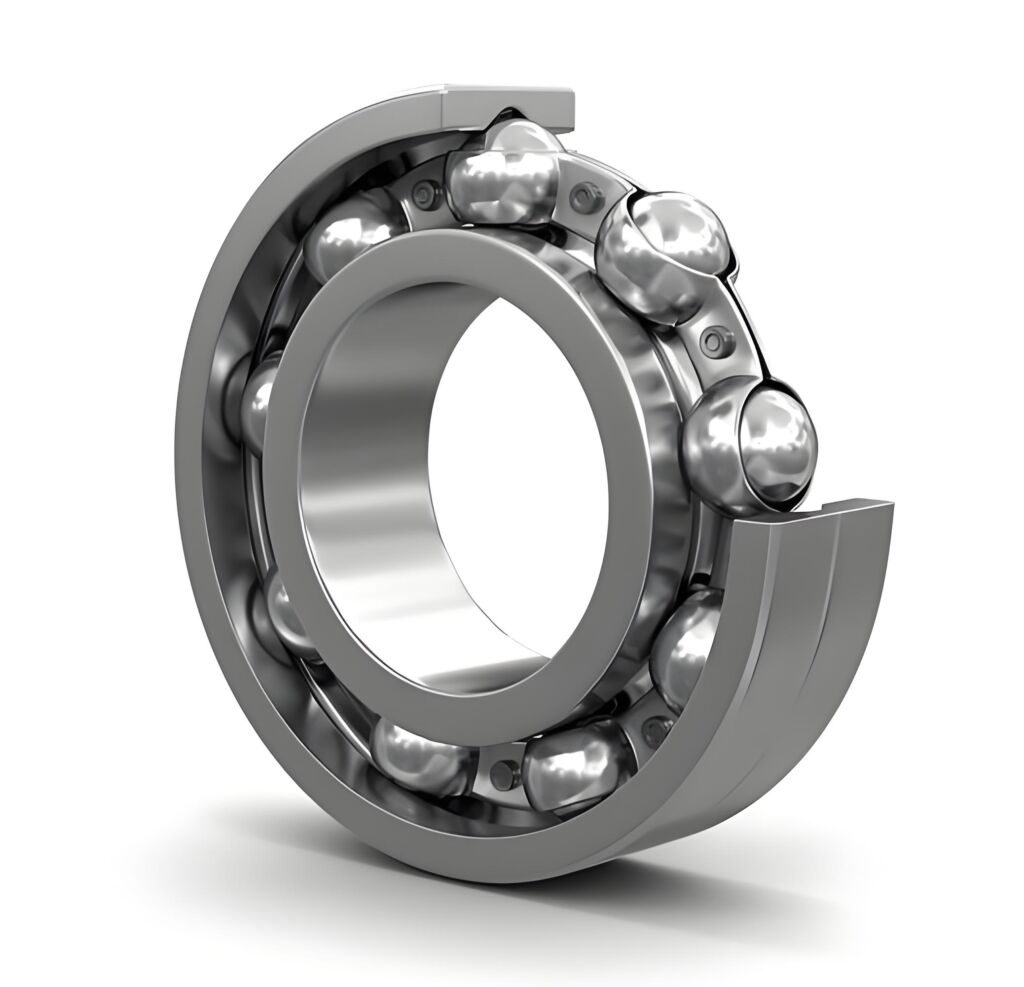

Deep Groove Ball Bearing

Deep groove ball bearing are the most representative type of rolling bearings. Compared to other bearing types of the same size, they feature low friction coefficients, high limiting speeds, simple structures, low manufacturing costs, high precision, minimal maintenance requirements, and a wide range of sizes and configurations, making them the most widely used bearing category. They primarily handle radial loads but can also accommodate some axial loads. When subjected solely to radial loads, the contact angle is zero.

Self-aligning ball bearing

Self-aligning ball bearing feature spherical inner rings and spherical outer rings with two raceways, assembled with spherical balls. The curvature center of the outer ring raceway aligns with the bearing center, providing the same self-aligning capability as self-aligning ball bearings. They automatically adjust to shaft or housing deflection without increasing bearing load. Self-aligning roller bearings can withstand radial loads and axial loads in both directions. With high radial load capacity, they are suitable for heavy loads and impact loads. Bearings with tapered inner bores can be mounted directly or installed on cylindrical shafts using locking sleeves or withdrawal sleeves. Cages are made from stamped steel plates or molded polyamide.

Thrust Ball Bearing

Thrust ball bearing are categorized into single-direction and double-direction types. They can only support axial loads and must never bear any radial loads. Thrust bearings consist of two parts: a fixed ring and a floating ring. The fixed ring fits tightly onto the shaft sleeve, while the floating ring is supported by the bearing housing. The rings and rolling elements are typically manufactured from high-strength, wear-resistant rolling bearing steel. After quenching, the surface hardness should reach HRC 60–65.